CORONA 40

CORONA 40 – Holiday detector

Corona 40 is a portable autonomous device for detecting pores, scratches, cracks, chips, tears, leaks and other defects in protective dielectric coatings with the application of pulsed high voltage while an electric spark is fixed by the device in the place of defect.

Features

Features

– High accuracy of maintaining the test voltage on the electrode (not more than 2%);

– Powerful test voltage generator (up to 50 W);

– False defect detection system;

– The device has a digital interface containing:

1. test voltage calculator, which allows to calculate the test voltage based on the known thickness of the tested coating;

2. user calibration mode, which allows to correct the device calibration by the user during the entire device lifetime if the appropriate measuring equipment is available;

3. single-electrode testing mode, allowing to detect through coating defects without a connected earthing wire;

4. defect counter;

– Operating temperature range: from minus 40 °C to plus 50 °C;

– The weight of the control unit does not exceed 0.65 kg;

– Autonomous operation time (up to 20 h at a test voltage of 40 kV using a fan electrode).

Basic technical characteristics

| Technical data | Corona 40 |

| Minimum thickness of tested coatings, µm | 50 |

| Maximum thickness of tested coatings, mm, at least | 25 |

| Type of holiday detector | Pulsed |

| Test voltage range, kV | From 0.7 to 40 |

| Pulse frequency, Hz | 50 |

| Voltage setting error, maximum | 2% |

| Weight of the control unit, g, maximum | 650 |

| Overall dimensions of the control unit (DxWxW), mm, maximum | 240х149х50 |

| Overall dimensions of the high-voltage transformer-holder (ØxD), mm, maximum | Ø83х380 |

Delivery set

Control unit Corona 40, case for control unit, high-voltage transformer-handle VT-40, ground wire with magnet and crocodile clip, extender, battery, fan electrode, battery charger, operating manual.

Electrodes

Rolling spring electrodes

Used to test insulating coatings on the outside surface of pipes. Available for pipes from 80 to 1620 mm diameter.

– Electrode B19 is made of beryllium bronze, spring diameter 19 mm. Designed for discontinuity testing of external coating on pipe with diameter from 80 to 424 mm.

– Electrode S19 is made of spring steel, spring diameter 19 mm. Designed for discontinuity testing of external coatings on pipes with diameter from 159 to 629 mm.

– Electrode S32 is made of spring steel, spring diameter 32 mm. Designed for discontinuity testing of external coatings of pipes with diameter from 425 to 1620 mm.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

Internal pipe disk electrodes

Used to inspect insulating coatings inside pipes with the diameter from 30 to 1420 mm.

Crescent-shaped electrodes

Designed to define places of continuity violation on insulating coatings of the pipes from 25 to 1020 mm diameter.

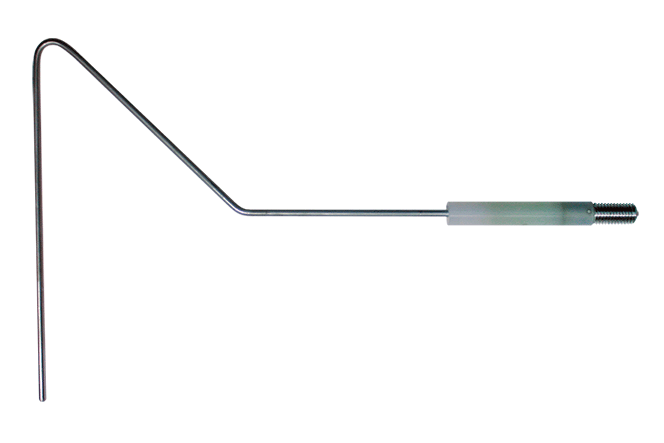

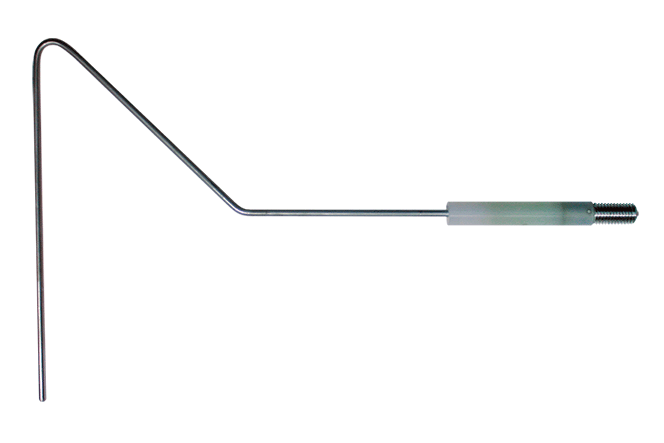

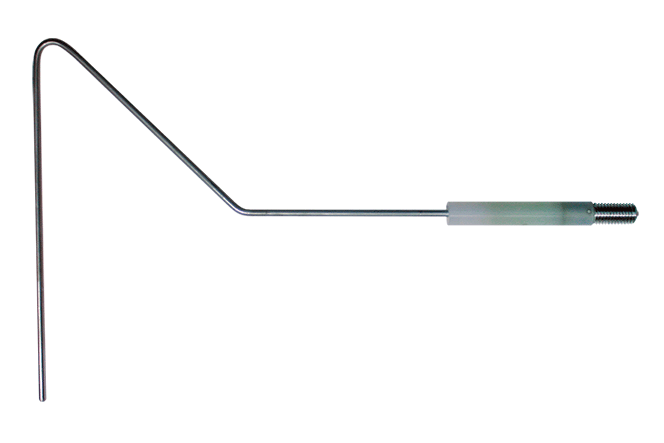

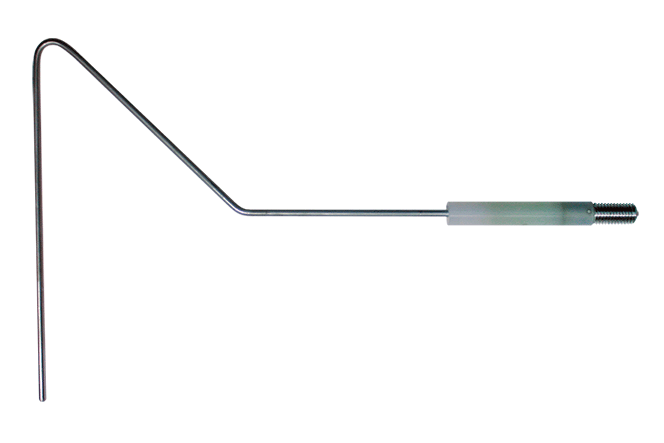

T-shaped electrodes

Used to test dielectric coatings of flat products.

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Round silicone rubber electrodes (with hole): Used to test coatings on the outside of small pipes (from 25 mm diameter).

Curved silicone rubber electrodes: Used for testing the external surface of pipes.

Rubber ring electrodes: Used for inspection of the outer surface of pipes with the diameter from 30 to 1420 mm

Special electrodes can be made according to customer’s own specification.

Purpose

Thickness measurement of products from metals and their alloys, thickness measurement under protective coatings, thickness measurement of non-metallic products (plastic, ceramics and other), which allow use of ultrasonic inspection methods.

Features

— colour display (TFT 2.4” 320 × 240);

— possibility of graphic display of ECHO signal in A-scan mode;

— B-scan;

— possibility of metal thickness measurement under coating (in ECHO-ECHO mode and PULSE-ECHO-COATING mode);

— possibility of coating thickness measurement (in PULSE-ECHO-COATING mode);

— automatic probe recognition.

Basic technical characteristics

— range of measured thicknesses (for steel)* Т, mm: with dual transducers: 0.5–300; with direct transducer (with delay line): 0.25–10 for steel; with specialized dual transducers (for measurements under protective coatings with thickness** up to 2.0 mm): 0.25–100;

— speed of ultrasound propagation, m/s: 1000–9999;

— measurement resolution, mm: 0.1; 0.01;

— measurement accuracy, mm: ±(0,005T + 0,05) in range of 0,25 to 10,0; ±(0,01T + 0,1) in range of 10,0 to 300,0;

— overall dimensions, mm: 120 × 57 × 20;

— power supply — LiPo rechargeable battery, V: 3.7;

— range of operating temperatures for devices (basic): –20…+50 °C;

— continuous operating time, h: 8;

— device weight no more than, g: 150.

* Depends on characteristics of inspected material and type of transducer.

** Depends on characteristics of coating material.

Delivery set

Delivery set

Measuring unit with two transducers, one of them for inspection of metallic products under coating (additional transducers can be ordered), charging unit, operating manual, miniUSB — USB cable for connection with PC, CD with software for transfer to PC and processing of measuring results, shock-proof small-sized case.

Guarantee period

— measuring unit — 3 years;

— transducers — 2 years.

B6-C Leaflet to download below

B6-C

Probes for thickness gauge B6-C

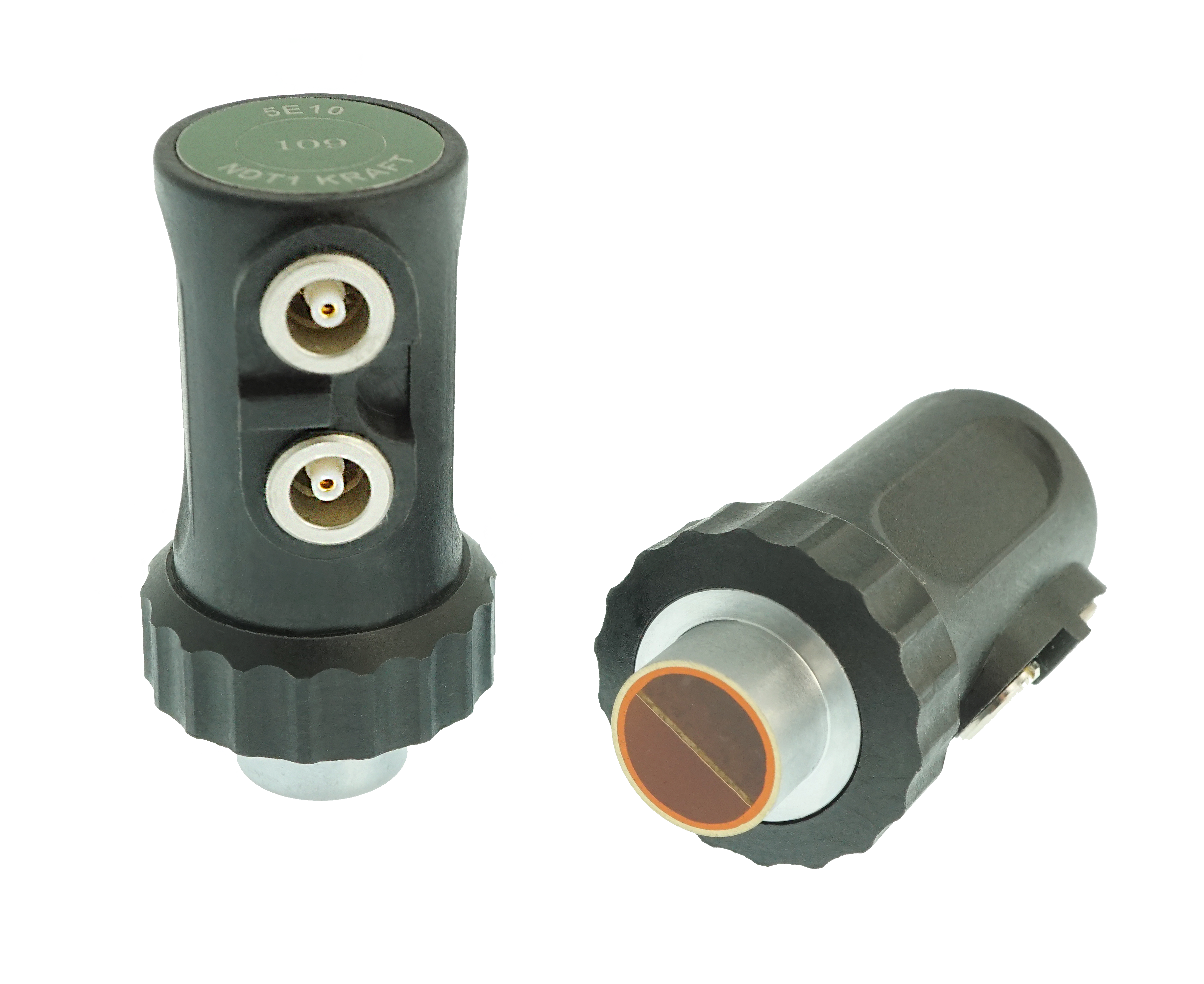

Dual element probe 5A10

Purpose

Measurement of thickness of walls of metal tanks, containers, pipes of big diameters.

Basic technical characteristics

— operation frequency, MHz, 5;

— thickness range (for steel), mm, from 1.0 to 200.0;

— through paint testing (only for flat objects), (max thickness of paint ≤0,5 mm);

— dimensions of contact surface, mm, Ø10;

— overall dimensions, mm, Ø18 x 26;

— operating temperature range: from -10° to +60 °C.

Particulars

Utilization of new synthetic materials provides low wear and good interfacing with rough surfaces.

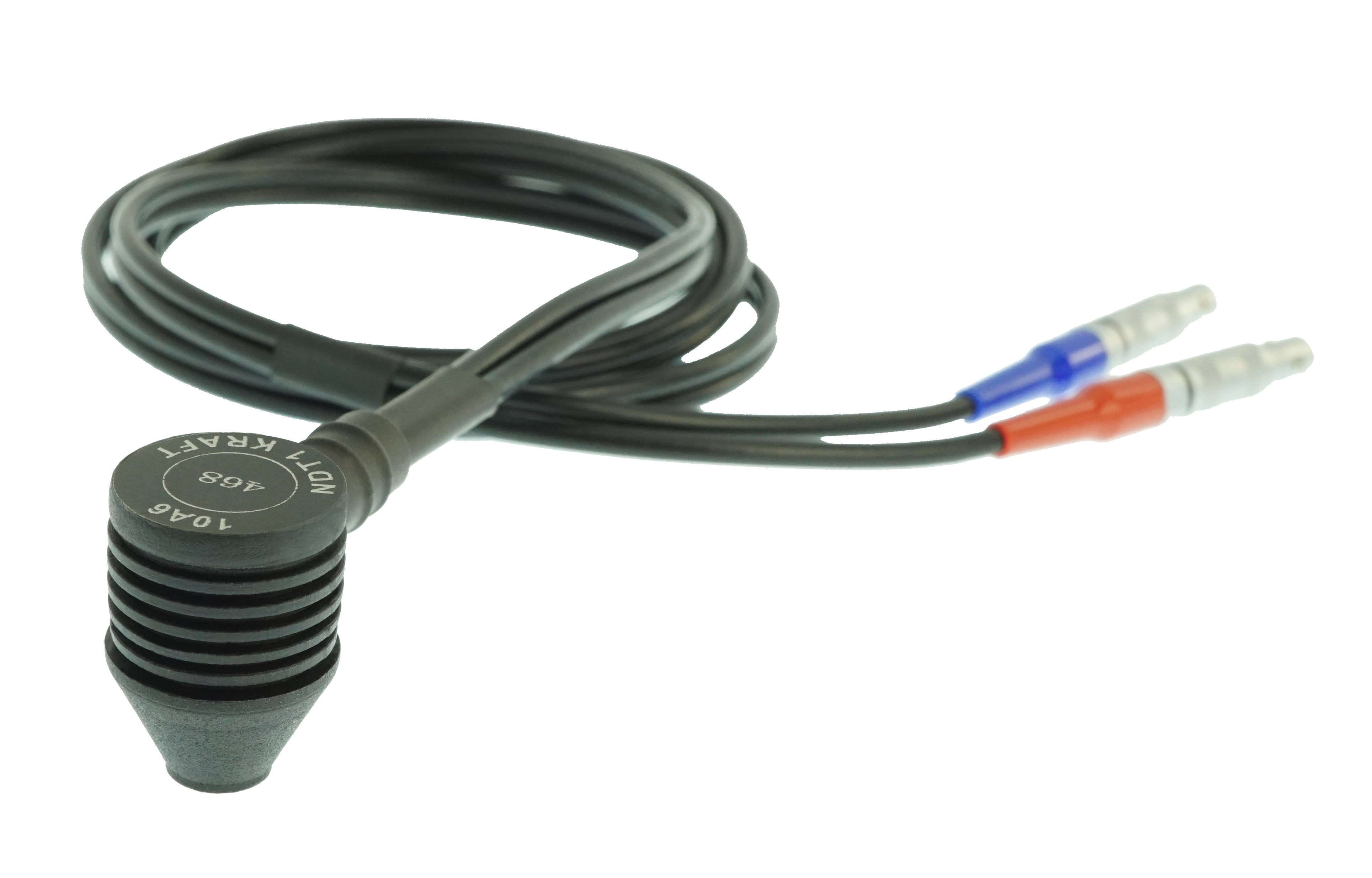

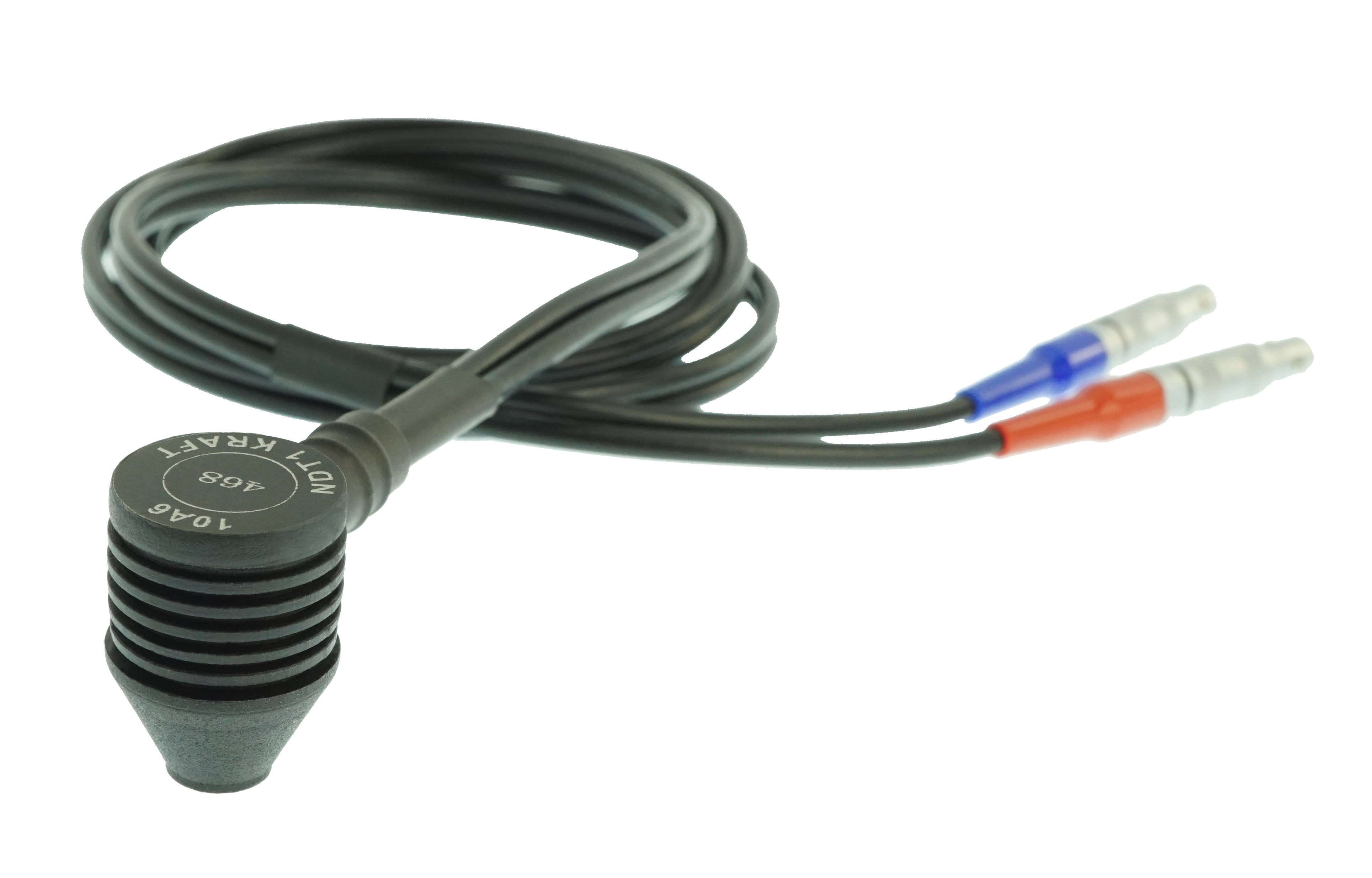

Dual element probe 10A6

Purpose

Measurement of thickness of pipes, curved areas of containers with small radius.

Basic technical characteristics

— operation frequency, MHz, 10;

— thickness range (for steel), mm, from 0.6 to 20;

— dimensions of contact surface, mm, Ø6;

— overall dimensions, mm, Ø14 x 26;

— operating temperature range: from -10° to +60 °C.

Particulars

Utilization of new synthetic materials provides low wear and good interfacing with rough surfaces.

Dual element probe 2.5A12

Purpose

Measurement of residual wall thickness of metallic and non-metallic products during manufacture, operation and repare.

Basic technical characteristics

— operation frequency, MHz, 2.5;

— thickness range (for steel), mm, from 3.0 to 200.0;

— dimensions of contact surface, mm, Ø15;

— overall dimensions, mm, Ø22 x 45;

— operating temperature range: from -10° to +60 °C.

Particulars

Good acoustic contact on rough and very rusted surface.

Small-sized dual element probe 10A4

Purpose

Measurement of wall thickness of pipes, thin metal plates.

Basic technical characteristics

— operation frequency, MHz, 10;

— thickness range (for steel), mm, from 0.5 to 10;

— dimensions of contact surface, mm, Ø4.5;

— overall dimensions, mm, Ø9 x 11;

— operating temperature range: from -10° to +60 °C.

Particulars

High locality, possibility of testing in hard-to-access locations (longerons, pipes with small diameter, etc).

Dual element high-temperature probe 5T12

Purpose

Intended for testing the thickness of hot metal parts. Used with thickness meter B6-С.

Basic technical characteristics

— operation frequency, MHz, 5;

— thickness range (for steel), mm, from 1.0 to 100.0;

— dimensions of contact surface, mm, Ø14;

— overall dimensions, mm, Ø26 x 48;

— operating temperature range: from -10° to +250 °C.

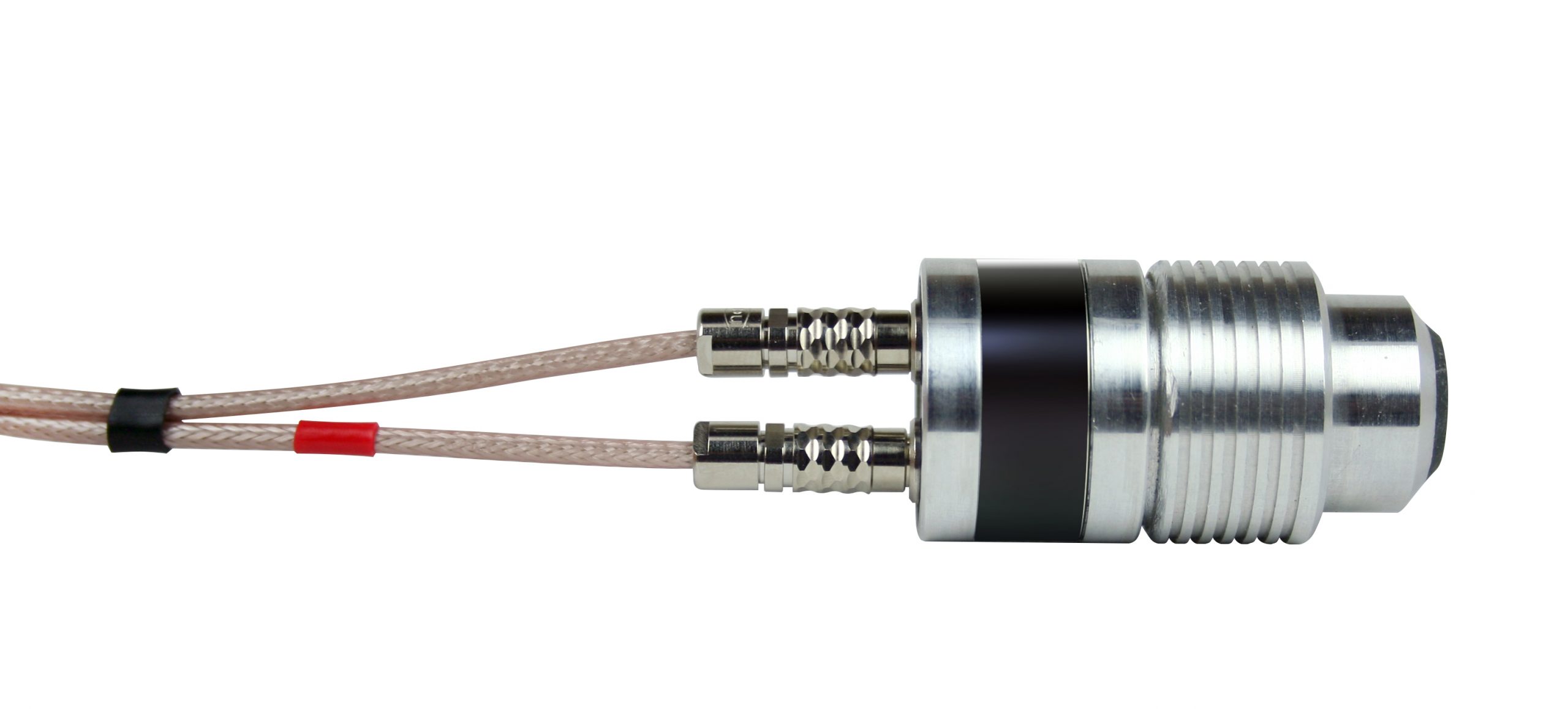

Through paint probes

Dual element probe 5E10

Purpose

Measuring of thickness of walls of metal tanks, conteiners, pipes of big diameters, also to read through and ignore coatings.

Basic technical characteristics

— operation frequency, MHz, 5;

— thickness range (for steel), mm, from 1.5 to 300.0 (in Pulse-Echo and Pulse-Echo-Coating); from 1.0 to 20.0 (in Echo-Echo mode);

— coating up to 2.0 mm (in Echo-Echo mode); coatings up to 1.0 mm (Pulse-Echo-Coating mode);

— dimensions of contact surface, mm, Ø12;

— overall dimensions, mm, Ø25 x 47;

— operating temperature range: from -10° to +60 °C.

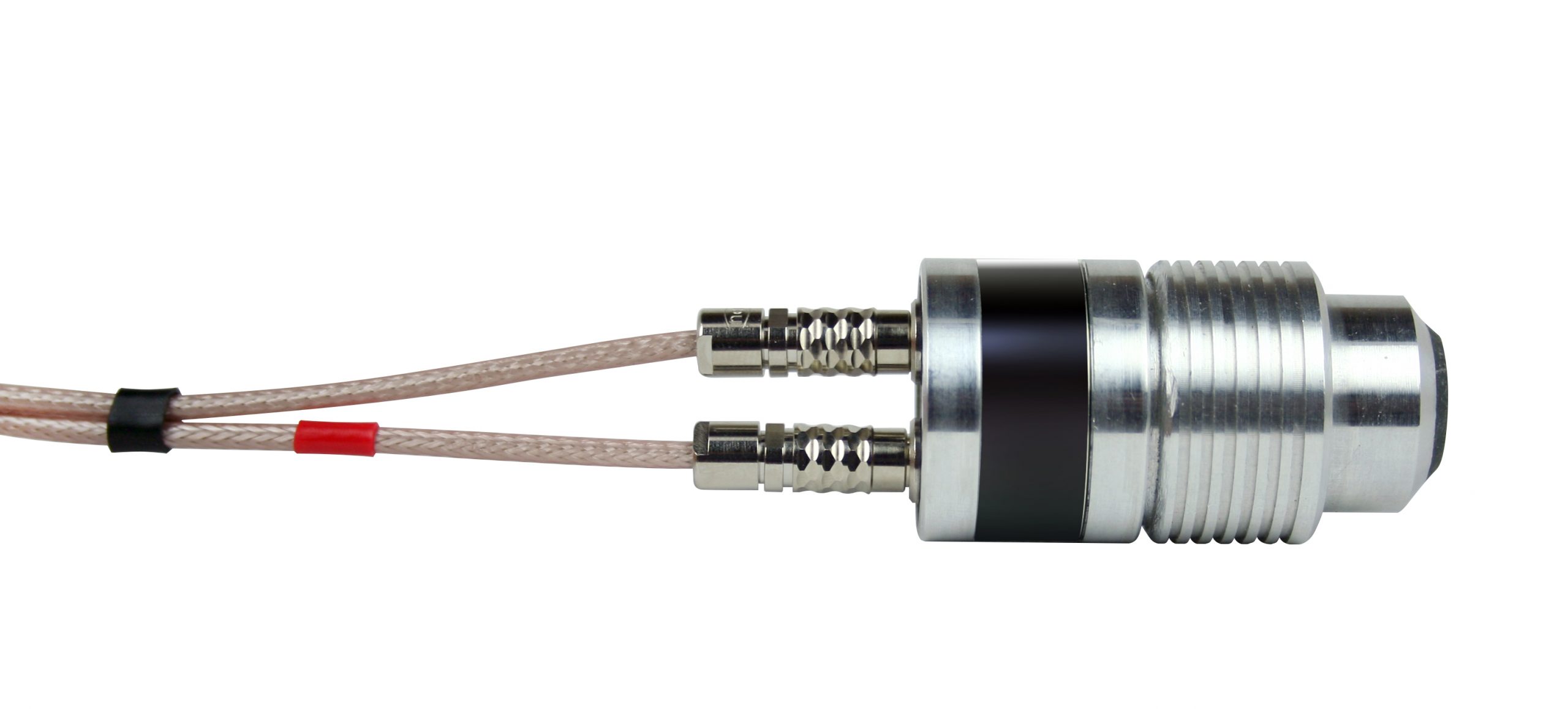

Dual element probe 10E6

Purpose

Measurement of thickness of pipes, curved areas of containers with small radius, also to read through and ignore coatings.

Basic technical characteristics

— operation frequency, MHz, 10;

— thickness range (for steel), mm, from 0.6 to 50.0 (in Pulse-Echo-Mode); from 0.6 to 10.0 (in Echo-Echo mode, coatings up to 1.0 mm); from 0.6 to 25.0 (in Pulse-Echo-Coating mode, coatings up to 0.5 mm)

— dimensions of contact surface, mm, Ø8;

— overall dimensions, mm, Ø25 x 47;

— operating temperature range: from -10° to +60 °C.

Particulars

Good acoustic contact on rough and very rusted surface.

Delay line probe 15DL6

Purpose

It’s recommends for thickness measurement of very thin materials.

Basic technical characteristics

— operation frequency, MHz, 15;

— thickness range (for steel), mm, from 0.25 to 10.0;

— thirough paint range, mm, from 0.25 to 10.0 (up to 2 mm coating);

— dimensions of contact surface, mm, Ø7.4;

— overall dimensions, mm, Ø14 x 25.5.

Particulars

High locality, possibility of testing in hard-to-access locations (longerons, pipes with small diameter, etc).

Single element probes with protective membrane (for Echo-Echo mode)

P111-S5C

Purpose

Measurement of residual wall thickness of metallic and non-metallic products for use with the gauge in Echo-Echo mode or Multiple-Echo mode to read through and ignore coatings.

Basic technical characteristics

— operation frequency, MHz, 5;

— thickness range (for steel), mm, from 1.0 to 200.0;

— dimensions of contact surface, mm, Ø16;

— overall dimensions, mm, Ø26 x 46;

— operating temperature range: from -10° to +60 °C;

— protective membrane: polyurethane membrane.

Particulars

Good acoustic contact on rough and very rusted surfaces. Through coatings measuring.

P111-S2C

Purpose

Measurement of residual wall thickness of metallic and non-metallic products for use with the gauge in Echo-Echo mode to read through and ignore coatings.

Basic technical characteristics

— operation frequency, MHz, 2.25;

— thickness range (for steel), mm, from 2.0 to 150.0;

— dimensions of contact surface, mm, Ø16;

— overall dimensions, mm, Ø26 x 46;

— operating temperature range: from -10° to +60 °C;

— protective membrane: polyurethane membrane.

Particulars

Good acoustic contact on rough and very rusted surfaces. Through coatings measuring.

Purpose

The detector is designed to reveal cracks, porosity, inadmissible thinning and other continuity violation of inner and outer protective dielectric coatings (paint and lacquers, powder, foil, bitumen and other dielectric coatings with thickness up to 1 mm) on metallic products with application of pulsed high voltage while an electric spark is fixed by the device in the place of continuity violation or inadmissible thinning.

Features

Features

— adjustable output voltage range: 0.7-4 kV;

— thickness of tested coatings: 0.04-1 mm;

— supplied with specialized rubber electrodes for paint and lacquers coatings;

— digital display showing voltage on electrode;

— high stability of voltage on electrode;

— adjustable sensitivity;

— quick battery replacement;

— battery charging in the device or separately while using the device (two batteries in the delivery set);

— high safety due to pulsed operation mode;

— small dimensions and light weight;

— large selection of replaceable electrodes for different purposes;

— inspection of coatings on concrete and other conductive substrates.

Basic technical characteristics

— coating thickness range: 0.04–1 mm;

— voltage on electrode adjustment range: 0.7–4 kV;

— output voltage adjustment resolution: 0.1 kV;

— type of indication of voltage amplitude on electrode– digital (3-digit);

— operating time from charged battery: up to 20 hours;

— device power source – built-in rechargeable battery: industrial for temperature range: -20 °C…+45 °C; low-temperature for temperature range: -45 °C…+45 °C;

— weight: control unit (with battery): 2 kg; high-voltage transformer-holder, VT1 – 1.3 kg;

— overall dimensions: control unit: 240 × 149 × 52 mm; high-voltage transformer-holder, VT1 Ø 50 × 350 mm.

Delivery set

Delivery set

High-voltage transformer-holder VT1, control unit, specialized rubber or brush electrode, extension rod, charging device, two rechargeable batteries, earth rod, magnet, earth lead, operating manual, thermo bag, case for storage and transportation.

The device may be completed with other replaceable rubber and brush electrodes with inspection zone from 50 to 400 mm and also specialized electrodes for internal and external pipe insulation inspection on pipe diameter from 60 to 1420 mm.

K1 Leaflet to download below

Holiday detectors

______________________________________________________________________________________________________________________________________

Electrodes

Rolling spring electrodes

Used to test insulating coatings on the outside surface of pipes. Available for pipes from 80 to 629 mm diameter.

– Electrode B19 is made of beryllium bronze, spring diameter 19 mm. Designed for discontinuity testing of external coating on pipe with diameter from 80 to 424 mm.

– Electrode S19 is made of spring steel, spring diameter 19 mm. Designed for discontinuity testing of external coatings on pipes with diameter from 159 to 629 mm.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

Internal pipe disk electrodes

Used to inspect insulating coatings inside pipes with the diameter from 30 to 1420 mm.

Crescent-shaped electrodes

Designed to define places of continuity violation on insulating coatings of the pipes from 25 to 1020 mm diameter.

T-shaped electrodes

Used to test dielectric coatings of flat products.

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Round silicone rubber electrodes (with hole): Used to test coatings on the outside of small pipes (from 25 mm diameter).

Curved silicone rubber electrodes: Used for testing the external surface of pipes.

Rubber ring electrodes: Used for inspection of the outer surface of pipes with the diameter from 30 to 1420 mm

Special electrodes can be made according to customer’s own specification.

Purpose

The device is designed to measure the thickness of products from metallic and nonmetallic materials (sheets, tanks, pipes, pipelines, bridges, metal containers, transport and other structures, including highly corroded, with incrustation, etc.) during operation to determine their corrosion state at or after the manufacture of energy, tube, engineering, shipbuilding, transportation and other enterprises.

Features

— high sensitivity, simplicity and ease of operation;

— automatic probe recognition;

— possibility of manual and automatic adjustment gain;

— colour display.

Basic technical characteristics

— measurement range* (for steel) T, mm: 0.5–200;

— sound velocity, m/s: 1000–9999;

— resolution (keypad selectable), mm: 0.1; 0.01;

— measurement accuracy, mm: ±(0.005T +0.05) in range of 0.5 to 99.99; ±(0.005T +0.1) in range of 100.0 to 200.0;

— possibility of gain adjustment;

— data memory: up to 500 measurements;

— automatic probe recognition;

— transfer of data to PC;

— display: colour display (TFT 2.4” 320 x 240);

— power supply – Li-ion rechargeable battery: 3.7V;

— operating temperature: from -10 °C to +50 °C;

— dimensions, mm: 120 × 57 × 20;

— weight, g: 150 including battery;

— connectors — Lemo 00.

* Depends on characteristics of inspected material and type of transducer.

Delivery set

Measuring unit with probes (number and type is agreed with customer), miniUSB — USB cable for connection with PC, CD with operating manual, carrying case.

Guarantee period

— measuring unit — 3 years;

— transducers — 2 years.

B2 Leaflet to download below

B2

Probes for thickness gauge B5

Dual element probe 5A10

Purpose

Measurement of thickness of walls of metal tanks, containers, pipes of big diameters.

Basic technical characteristics

- operation frequency, MHz, 5;

- thickness range (for steel), mm, from 1,0 to 200,0;

- dimensions of contact surface, mm, Ø10;

- overall dimensions, mm, Ø18 x 26;

- operating temperature range: from -10° to +60°C.

Particulars

Utilization of new synthetic materials provides low wear and good interfacing with rough surfaces.

Dual element polyimide probe 10A6

Purpose

Measurement of thickness of pipes, curved areas of containers with small radius.

Basic technical characteristics

- operation frequency, MHz, 10;

- thickness range (for steel), mm, from 0,6 to 20;

- dimensions of contact surface, mm, Ø6;

- overall dimensions, mm, Ø14 x 26;

- operating temperature range: from -10° to +60°C.

Particulars

Utilization of new synthetic materials provides low wear and good interfacing with rough surfaces.

Dual element high-temperature probe 5T12

Purpose

Intended for testing the thickness of hot metal parts. Used with thickness meter B5.

Basic technical characteristics

- operation frequency, MHz, 5;

- thickness range (for steel), mm, from 1,0 to 200,0;

- dimensions of contact surface, mm, Ø14;

- overall dimensions, mm, Ø27 x 50;

- operating temperature range: from -10° to +250°C.

Small-sized dual element probe 10A4

Purpose

Measurement of wall thickness of pipes, thin metal plates.

Basic technical characteristics

- operation frequency, MHz, 10;

- thickness range (for steel), mm, from 0,5 to 10;

- dimensions of contact surface, mm, Ø4,5;

- overall dimensions, mm, Ø9 x 11;

- operating temperature range: from -10° to +60°C.

Particulars

Velká oblast měření, možnost měření v těžko dostupných místech (nosníky, potrubí s malým průměrem atd).

ED – Wireless eddy current flaw detector

Ergonomic compact flaw detector combining reliability, wide functionality and ease of use.

Purpose

Detection and depth measurement of surface cracks in products from ferromagnetic steels and cast iron, aluminium, titanium alloys and low magnetic corrosion-resistant steels.

Features

– inspection through coatings or contamination, including variable thicknesses

– selection of material of the inspected object

– acoustic alarm and vibration alarm when the threshold is exceeded

– display of crack depth with resolution of 0.01 mm

– Bluetooth wireless connection to smartphones and tablets

– can be equipped with a secure tablet

Delivery set

eddy current flaw detector, charging device with USB-C cable, operating manual, secure tablet (supplied on customer request), reference artificial defects samples (supplied on customer request), case for storage and transport.

Basic technical characteristics

| Display and signalization | Colour LCD display,

acoustic alarm, vibration alarm |

| Resolution of crack depth display | 0.1 mm |

| Range of operating temperature | -20…+50 °С |

| Power supply | Built-in Li-ion rechargeable battery |

| Continuous operation time | 12 h |

| Charger connection | socket USB-C |

RSWA F2 – Ultrasonic quality inspection platform

RSWA F2 is an ultrasonic device designed for non-destructive evaluation and quality inspection for various applications, such as spot welds and adhesive joints testing. RSWA F2 is a result of the systematic advanced development of the field-proven and successful RSWA F1 from Tessonics. F2 device is 50% lighter and thinner and provides unique ease of use due to the high-resolution 10.1″ display and the possibility for wireless connection to new Tessonics Data Service.

The Tessonics Data Service (TDS) is a data management software that provides the possibility to manage all connected RSWA F2 instruments and to keep software revisions up-to-date. Additionally, measurement data can be made available – almost in real-time – to any user within a network and appropriate authorization. For this, no additional software is required, the user can directly access data with every internet capable device.

Together with the RSWA F2, a new and unique transducer technology is introduced. While for comparable instruments on the market the complete transducer has to be exchanged in case of a defect cable, cables can be replaced on RSWA F2 transducers separately which reduces maintenance costs significantly.

The unique technology of multi-channel matrix arrays allows the portable and ease to use device to produce internal ultrasonic C-scan images of defects and structures. Tessonics algorithms evaluate the quality determining features that can be compared to predefined specifications. To further improve the operator’s experience, the software assists in making decisions in automatic or semi-automatic mode, guides through the inspection routines with intuitive graphics, saves the record of the inspected parts and integrates into a large infrastructure with centralized inspection planning and reporting.

- Resistance Spot Weld Analyzer (RSWA)

- Adhesive Bonding Inspection System (ABIS)

- transducers with built-in identification system

- unrestricted matrix element count

- single-frame and continuous data acquisition modes

- standard 52-element transducer

- new 120-element with 15 mm diameter coverage

- unique technology to replace transducer cables in case of damage

- RSWA-Mode: 2T and 3T (2 & 3 plates) stack

- ABIS-Mode: glued stacks

- Steel and Aluminum

- 0.6 – 2.4 mm plate thickness

- bare, coated and painted

Specifications

Processor

– Apollo Lake Intel Pentium N4200 Quad Core, 1.1 GHz, up to 2.5 GHz

Display

– 10.1” IPS panel, 1920 x 1200

– Resistive touch screen

– Replaceable screen protector

Memory

– 4 GB DDR3L

Storage

– 256 GB SSD

Communications

– WLAN 802.11 a/b/g/n/ac

– Bluetooth®

External ports

– 2 x USB 2.0

– HDMI

– DC-In

Power

– 2 x Smart Li-ion batteries, 14.4 V, 49 Wh

– Average battery run time: 9-12 hours

– DC adapter: 100-240 V, 65 W

Temperature Range

– Operational: 5° – 40° C (41° – 104° F)

– Storage: -20° – 60° C (-4° – 140° F)

Mechanical

– Weight with batteries: 2.3 kg (5 lb)

– Dimensions: 27.6 x 22 x 57 cm (10.9 x 8.6 x 2.3 in)

– Adjustable stand

– Machined aluminum enclosure

RSWA F2 Leaflet to download below

RSWA F2

RSWA F2 Transducers

For the RSWA F2 a unique transducer technology has been developed that provides the possibility to replace cables in case of damage. The cable can be replaced by the operator by simply loosening respective screws which significantly lowers maintenance costs.

The RSWA F2 transducers are available in a 52-element or in a new 120-element version.

- Matrix-array transducer

- 52 or 120 elements (diameter: 10 or 15 mm)

- 1,25 mm x 1,25 mm pitch

- 15 MHz

- 2 m cable length

- replaceable hard delay line

- replaceable cable, same cable type for both transducer versions

Pencil Probe

The Pencil Probe for RSWA F-2 enables testing even in hard-to-reach places. With its housing diameter of only 16 mm and the length of 100 mm it is designed in the shape of a welding electrode and therefore also reaches deep positioned spot welds.

With its 52 elements with the pitch of 1.25 x 1.25 mm it has the same ultrasonic characteristics as Tessonics proven RSWA standard probes.

In addition, the probe has also the option of replacing the cable in the case of damage without having to replace the entire probe. The probe and cable are simply connected to one another by industry-proven Lemo connectors.

Features

– Matrix-array transducer

– 52 elements (diameter: 10 mm)

– 1,25 x 1,25 mm pitch

– 15 MHz

– 2 m cabel lenght

– 16 mm maximum housing diameter

– Aprox. 100 mm total lenght (without cabel)

– Replacable hard delay line

– Replacable cable, Lemo connector

ABIS

The Adhesive Bond Inspection System (ABIS) was developed by Tessonics Inc. for NDT of adhesive joints in automotive and aerospace assemblies. This system employs a matrix array of small flat ultrasonic transducers for evaluation of the adhesive joint. The reverberating waveforms recorded by the array elements are processed to obtain an informative parameter, whose two-dimensional distribution is presented as a C-scan. The C-scans show the lateral location of “adhesive/no-adhesive” regions in the joint.

- One side access

- Two dimensional 10 mm x 10 mm acoustic image of the adhesive coverage

- Automatic determination of the width of the adhesive bead

- Real time A–scan and C –scan display

- Lateral resolution – 1 mm

Purpose

The detector is designed to reveal cracks, porosity, inadmissible thinning and other continuity violation of inner and outer protective coatings on metallic products with application of pulsed high voltage while an electric spark is fixed by the device in the place of continuity violation or inadmissible thinning.

Features

Features

— adjustable output voltage range: 2–35 kV;

— thickness of tested coatings: up to 12 mm;

— digital display showing voltage on electrode;

— high stability of voltage on electrode;

— adjustable sensitivity;

— quick battery replacement;

— battery charging in the device or separately while using the device (two batteries in the delivery set);

— high safety due to pulsed operation mode;

— large selection of replaceable electrodes for different purposes;

— specialized disc electrodes for coating inspection inside tubes with diameter from 89 to 520 mm and length up to 14 m;

— small dimensions and light weight;

— inspection of coatings on concrete and other conductive substrates.

Basic technical characteristics

— Type of indication of voltage amplitude on electrode– digital (3-digit);

— Output voltage adjustment resolution: 0,1 kV;

— Diameter of inspected pipes while using spring electrodes: up to 1620 mm;

— Diameter of pipes during internal insulation inspection while using disc electrodes: from 30 mm to 1420 mm;

— Device power source — built-in rechargeable battery: industrial for temperature range: -20 °C…+45 °C; low-temperature for temperature range: -45 °C…+45 °C; inspection voltage stability: 2 %;

— Weight: control unit (with battery): 2 kg; high-voltage transformer-holder VT2 – 1,3 kg;

— Operating time from charged battery: up to 8 hours;

— Overall dimensions: control unit: 240 × 149 × 52; high-voltage transformer-holder VT2 – 57 × 380 mm.

Delivery set

Delivery set

High-voltage transformer-holder VT2, control unit, brush (fan) electrode and T-shaped electrode, extension rod, charging device, two rechargeable batteries, earth rod, earth lead with magnet and crocodile clip, operating manual, thermo carrying bag, case for storage and transportation.

The device can be completed with additional rechargeable batteries and the following replaceable electrodes:

— T-shaped electrode

of small dimensions, crescent-shaped electrode, brush (fan) electrode, flat, rubber and hair electrodes with inspection zone from 50 to 400 mm;

— Spring electrodes with one clamping for pipe diameter up to 1620 mm.

K2.1 Leaflet to download below

Holiday detectors

______________________________________________________________________________________________________________________________________

Electrodes

Rolling spring electrodes

Used to test insulating coatings on the outside surface of pipes. Available for pipes from 80 to 1620 mm diameter.

– Electrode B19 is made of beryllium bronze, spring diameter 19 mm. Designed for discontinuity testing of external coating on pipe with diameter from 80 to 424 mm.

– Electrode S19 is made of spring steel, spring diameter 19 mm. Designed for discontinuity testing of external coatings on pipes with diameter from 159 to 629 mm.

– Electrode S32 is made of spring steel, spring diameter 32 mm. Designed for discontinuity testing of external coatings of pipes with diameter from 425 to 1620 mm.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

Internal pipe disk electrodes

Used to inspect insulating coatings inside pipes with the diameter from 30 to 1420 mm.

Crescent-shaped electrodes

Designed to define places of continuity violation on insulating coatings of the pipes from 25 to 1020 mm diameter.

T-shaped electrodes

Used to test dielectric coatings of flat products.

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Round silicone rubber electrodes (with hole): Used to test coatings on the outside of small pipes (from 25 mm diameter).

Curved silicone rubber electrodes: Used for testing the external surface of pipes.

Rubber ring electrodes: Used for inspection of the outer surface of pipes with the diameter from 30 to 1420 mm

Special electrodes can be made according to customer’s own specification.

ED – Wirele ss eddy current flaw detector

ss eddy current flaw detector

Ergonomic compact flaw detector combining reliability, wide functionality and ease of use.

Purpose

Detection and depth measurement of surface cracks in products from ferromagnetic steels and cast iron, aluminium, titanium alloys and low magnetic corrosion-resistant steels.

Features

– inspection through coatings or contamination, including variable thicknesses;

– selection of material of the inspected object;

– acoustic alarm and vibration alarm when the threshold is exceeded;

– display of crack depth with resolution of 0.01 mm;

– Bluetooth wireless connection to smartphones and tablets;

– can be equipped with a secure tablet.

Delivery set

eddy current flaw detector, charging device with USB-C cable, operating manual, secure tablet (supplied on customer request), reference artificial defects samples (supplied on customer request), case for storage and transport.

Basic technical characteristics

| Display and signalization | Colour LCD display, acoustic alarm, vibration alarm |

| Resolution of crack depth display | 0.1 mm |

| Range of operating temperature | -20…+50 °С |

| Power supply | Built-in Li-ion rechargeable battery |

| Continuous operation time | 12 h |

| Charger connection | socket USB-C |

Flaw detector versions

ED-1mm and ED-1mm-R

ED-1mm and ED-1mm-R

Purpose

Eddy current flaw detector with high-local sensitive element designed for detection and depth measurement of short surface defects on smooth and rough surface.

| Type of sensitive element | absolute | |

| Diameter of sensitive elements | 1 mm | |

| Radius of area of influence | 5 mm | |

| Minimum size of detectable defects | depth 0.15 (0.05*) mm | |

| length, 2 mm | ||

| Defect depth measurement range | from 0.2 to 2 mm | |

| Main permissible error of defect depth measurement | ± (15 % + 0.1) mm | |

| Minimum length of defects when measuring their depth | 8 mm | |

| Maximum coating thickness | at which defect depth measurement with the declared measurement error is ensured | 0.3 mm |

| at which defect detection is ensured | 0.5 mm | |

| Maximum surface roughness | Rz 20 µm | |

| Scanning speed | when detecting defects | from 3 to 150 mm/s |

| when measuring depth of defects | up to 10 mm/s | |

| Overall dimensions | ED-1mm | 156 х 28 х 27 mm |

| ED-1mm-R | 180 х 28 х 27 mm | |

* – for the material group of inspected objects Steel

ED-3mm and ED-3mm–R

Purpose

Detection and depth measurement of defect on rough surface.

| Type of sensitive element | absolute | |

| Diameter of sensitive element | 3 mm | |

| Radius of area of influence | 15 mm | |

| Minimum size of detectable defects | depth 0.2 (0.1*) mm | |

| length, 6 mm | ||

| Defect depth measurement range | from 0.5 to 5 mm | |

| Main permissible error of defect depth measurement | ± (15 % + 0.2) mm | |

| Minimum length of defects when measuring their depth | 25 mm | |

| Maximum coating thickness | at which defect depth measurement with the declared measurement error is ensured | 1 mm |

| at which defect detection is ensured | 1.5 mm | |

| Maximum surface roughness | Rz 320 µm | |

| Scanning speed | when detecting defects | from 10 to 500 mm/s |

| when measuring depth of defects | up to 50 mm/s | |

| Overall dimensions | ED-3mm | 149 х 28 х 27 mm |

| ED-3mm-R | 163 х 28 х 36 mm | |

* – for the material group of inspected objects Steel

ED-6mm

ED-6mm

Purpose: detection and depth measurement of defects on very rough surfaces, depth measurement of deep defects.

| Type of sensitive element | absolute | |

| Diameter of sensitive element | 6 mm | |

| Radius of area of influence | 30 mm | |

| Minimum size of detectable defects | depth 1 (0.3*) mm | |

| length, 12 mm | ||

| Defect depth measurement range | from 1 (0.5*) to 10 mm | |

| Main permissible error of defect depth measurement | ± (15 % + 0,5) mm | |

| Minimum length of defects when measuring their depth | 50 mm | |

| Maximum coating thickness | at which defect depth measurement with the declared measurement error is ensured | 2 mm |

| at which defect detection is ensured | 3 mm | |

| Maximum surface roughness | Rz 640 µm | |

| Scanning speed | when detecting defects | from 20 to 1000 mm/s |

| when measuring depth of defects | up to 100 mm/s | |

| Overall dimensions | 154 х 28 х 27 mm | |

* – for the material group of inspected objects Steel

ED-W10mm

ED-W10mm

Purpose: detection and measurement of defect depths in objects with highly inhomogeneous electromagnetic properties and rough surfaces, such as weld seams, near seam zone and heat affected zone.

| Type of sensitive element | In accordance with ISO 17643 | |

| Diameter of sensitive element | 10 mm | |

| Radius of area of influence | 30 mm | |

| Minimum size of detectable defects | depth 0.5 mm | |

| length, 10 mm | ||

| Defect depth measurement range | from 0.5 to 10 mm | |

| Main permissible error of defect depth measurement | ± (20 % + 0.5) mm | |

| Minimum length of defects when measuring their depth | 30 mm | |

| Maximum coating thickness | at which defect depth measurement with the declared measurement error is ensured | 1 mm |

| at which defect detection is ensured | 2 mm | |

| Maximum surface roughness | Non standardized | |

| Scanning speed | when detecting defects | from 10 to 500 mm/s |

| when measuring depth of defects | up to 50 mm/s | |

| Overall dimensions | 152 х 28 х 27 mm | |

ED-L20mm, ED-L30mm, ED-L40mm

ED-L20mm, ED-L30mm, ED-L40mm

Purpose: wide-coverage transducer designed for detection and measurement of defect depth on objects of large area.

| Version | ED-L20mm | ED-L30mm | ED-L40mm | |

| Type of sensitive element | Differential | |||

| Diameter of sensitive element | 20 mm | 30 mm | 40 mm | |

| Radius of area of influence | 40 mm | 60 mm | 80 mm | |

| Minimum size of detectable defects | depth 0.5 mm | depth 1 mm | depth 2 mm | |

| length 10 mm | length 15 mm | length 20 mm | ||

| Defect depth measurement range | from 0.5 to 5 mm | from 1 tо 10 mm | from 1 to 10 mm | |

| Main permissible error of defect depth measurement | ± (20 % + 0.5) mm | |||

| Minimum length of defects when measuring their depth | 20 mm | 30 mm | 40 mm | |

| Maximum coating thickness | at which defect depth measurement with the declared measurement error is ensured | 2 mm | 3 mm | 4 mm |

| at which defect detection is ensured | 4 mm | 6 mm | 8 mm | |

| Maximum surface roughness | Rz 160 µm | Rz 640 µm | Rz 640 µm | |

| Scanning speed | when detecting defects | from 20 to 1000 mm/s | from 30 to 1500 mm/s | from 40 to 2000 mm/s |

| when measuring depth of defects | up to 10 mm/s | up to 15 mm/s | up to 20 mm/s | |

| Overall dimensions | 147 х 30 х 28 mm | 148 х 40 х 29 mm | 150 х 50 х 38 mm | |

RSWA F1 – Resistance Spot Weld Analyzer

RSWA F1 is an ultrasonic device designed for non-destructive evaluation and quality inspection of resistance spot welds.

RSWA F1 from Tessonics is a portable and easy to use device capable of producing images of spot weld’s internal structures. In addition to live on-screen image, the device estimates the nugget diameter and compares it with predefined minimum nugget requirements.

Using the unique technology of multi-channel ultrasonic matrix transducer, RSWA collects data from the surface and from the internal structures of the nugget. Special algorithms use this data to reconstruct the image of the spot weld and estimate the average diameter of the nugget area in real time.

Features

– single frame a data acquisition modes

– automatic and manual nugget size estimation

– automatic detection of scanning depth inside the metal

– two levels of user interface complexity depending on operator skills

– built-in reporting system and file storage

Applications

Metal stacks: 2T and 3T; 0.6–2.4 mm plate thicknesses

Types of materials: mild steel, high strength steel, dual phase ultra high strength steel

Coatings: bare, zinc coating (galvanized, galvaneal), e-coating, paint

Purpose

The detector is designed specifically to detect flaws in waterproof coatings on conductive substrate (e.g. steel, concrete, aluminium foil) of roof systems with the application of high voltage while an electric spark is fixed by the device in the place of the fault.

This dry method does not require wetting the waterproof membrane surface before the test, which allows to inspect both flat and complex-shaped surfaces with a significantly higher speed.

Features

Features

— inspection of coatings on metal and concrete backing;

— test width up to 1 meter;

— device grounding anywhere on the roof;

— adjustable output voltage range: 2–35 kV;

— thickness of tested coatings up to 12 mm;

— digital display showing voltage on electrode;

— high stability of voltage on electrode;

— adjustable sensitivity;

— quick battery replacement;

— battery charging in the device or separately while using the device (two batteries in the delivery set);

— high safety due to pulsed operation mode;

— large selection of replaceable electrodes for different purposes;

— small dimensions and light weight;

Basic technical characteristics

— Type of indication of voltage amplitude on electrode– digital (3-digit);

— Output voltage adjustment resolution: 0,1 kV;

— Device power source — built-in rechargeable battery: industrial for temperature range: -20 °C…+45 °C; low-temperature for temperature range: -45 °C…+45 °C; inspection voltage stability: 2 %;

— Weight: control unit (with battery): 2 kg; high-voltage transformer-holder VT2 – 1,3 kg;

— Operating time from charged battery: up to 8 hours;

— Overall dimensions: control unit: 240 × 149 × 52; high-voltage transformer-holder VT2 – 57 × 380 mm.

Delivery set

High-voltage transformer-holder VT2, control unit, brush (fan) electrode and 1 meter T-shaped electrode, extension rod, charging device, two rechargeable batteries, up to 50 m earth lead with magnet a crocodile clip, operating manual, thermo carrying bag, case for storage and transportation.

The device can be completed with additional rechargeable batteries and the following replaceable electrodes:

— T-shaped electrode of small dimensions, brush (fan) electrode, flat rubber and hair electrodes with inspection zone from 50 to 400 mm;

K2.1 Leaflet to download below

Holiday detectors

______________________________________________________________________________________________________________________________________

Electrodes

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

T-shaped electrodes

Used to test dielectric coatings of flat products.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Special electrodes can be made according to customer’s own specification.

+420 267 313 996

+420 267 313 996