K6-C

Product Description

K6-C Multifunctional Coating Thickness Gauge

Purpose

Thickness measurement of:

Thickness measurement of:

— galvanic (zinc, chromium, nickel, cadmium, silver, tin and other) coatings on steel products;

— galvanic (zinc, chromium, nickel, cadmium, silver, tin and other) coatings on products from non-ferrous metals;

— paint, lacquer, enamel, powder, mastic and other dielectric coatings on steel products;

— anodic oxide, phosphate and other dielectric coatings on ferrous and non-ferrous metals;

— special dielectric and metallic thick coatings, plated coatings;

— coatings on the internal surfaces of pipes and cylindrical products;

— copper foils on printed circuit boards;

— sheets of conductive non-ferrous materials and galvanic coatings on products from dielectric materials;

— two layers coatings;

— protective layer of concrete and determination of steel reinforcement position in concrete;

— wall thickness of large products from fiberglass and carbon fiber reinforced plastics during manufacture and delivery with one side and two sides access;

Measurement of groove depth and evaluation of surface roughness after sand blasting or grit blasting;

Control of climatic conditions (air humidity, air and metal surface temperature, dew point temperature and determination of TΔ parameter).

Features

— TFT colour display with 2.4” diagonal and a built-in Li-Ion battery;

— shockproof ergonomic body with rubberized corners;

— keyboard with functional keys that change their purpose depending on the mode of operation of the device and user-friendly and intuitive interface;

— additional modes and device settings;

— extended set of wear-resistant ergonomic small-sized transducers;

— support for transducers with several calibration characteristics (up to 6 for PH3 series probes, up to 4 for NF-G probes, up to 2 F-G probes).

Basic technical characteristics

— the range of thickness control: 0.5 µm…120 mm (depends on connected transducer);

— number of transducers: unlimited (according to customer’s choice);

— temperature range:for device: -10…+40 °C (-30 ° C for frost-resistant version), for transducers: -40…+50 °C (up to +350 °C for high temperature transducers);

— calibration methods: additive one-point, two-point, one-point with automatic multiplicative correction;

— power supply: built-in Li-Ion battery in 3.7-4.2 V, 1500-1700 mAh;

— continuous operation time: min. 12 hours;

— connectivity with PC: USB 2.0 channel;

— overall dimensions: 60 × 125 × 25 mm;

— weight of electronic unit: 120 g;

— charging time: 4 h.

Delivery set

Delivery set

Measuring unit with transducers (number and modification depend on customer’s choice), charging unit, set of coating thickness reference specimens and basis reference specimens (based on selected transducers), mini-USB — USB A Type cable for connection with computer, operating manual, shockproof case.

Guarantee period

— measuring unit — 3 years;

— transducers — 2 years.

K6-C Leaflet to download below

K6-C – product leaflet

Probes for the Magneto-Inductive measurement method

Probes F for K6-C contain one calibration characteristics for coatings thickness measurement on ferromagnetic bases.

F0

Probe for galvanic (zinc, chrome, cadmium, etc.) and dielectric (plastic, paint, etc.) coatings on small-sized parts (with small radius of curvature) and in hard-to-reach areas made of ferromagnetic materials.

- measurement range, T: 0-300 µm (0.3 mm);

- measurement accuracy, ±(0,02T+1) µm

- diameter of test area, Øm, mm: 3 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 4,5 (1).

- dimensions, mm: Ø9×115

Particulars

Probe of pencil type with fixed measurement system. Minimum diameter of test area provides complete tuning out from influence of coating electric conductivity.

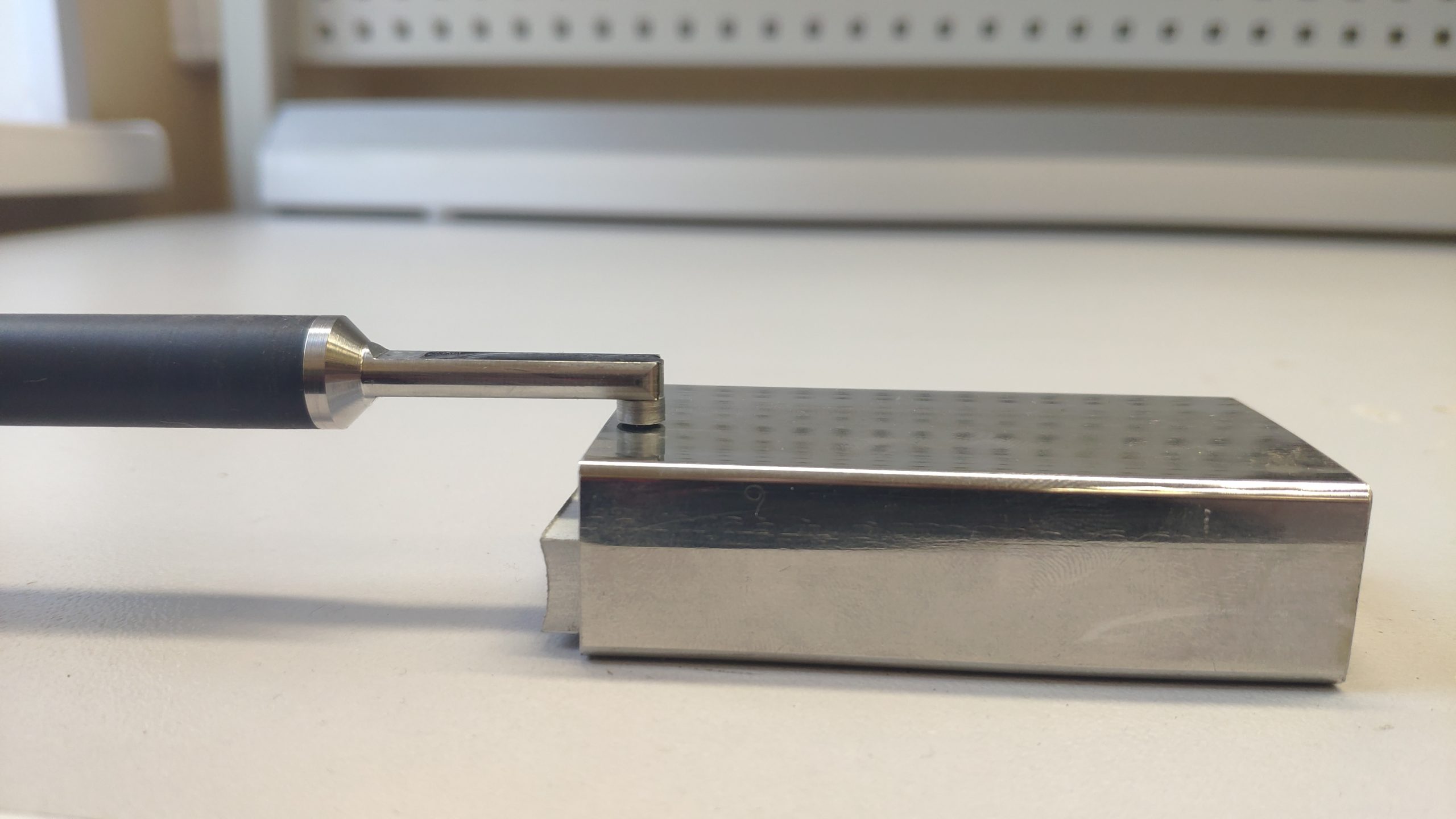

F0/90

Probe for galvanic (zinc, chrome, cadmium, etc.) and dielectric (plastic, paint, etc.) coatings on small-sized parts (with small radius of curvature) and in hard-to-reach areas made of ferromagnetic materials.

Technical features

- measurement range, T: 0-300 µm (0.3 mm);

- measurement accuracy, ±(0,02T+1) µm

- diameter of test area, Øm, mm: 3 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 4,5 (1).

- dimensions, mm: Ø20×127

NEW:

F0/90 MINI

Transducer F0/90 MINI in the set with the specialised K6-C thickness gauges for thickness measurement of nonferromagnetic coatings on hard to reach places of products from ferrous metals.

Technical features

- measurement range, T: 0-300 µm (0.3 mm);

- measurement accuracy: ±(0,01T+2) µm;

- diameter of test area, Øm, mm: 4 ;

- dimensions, mm: Ø7×29.

F1

Probe for measuring of galvanic (zinc, chrome, cadmium, etc.) and dielectric (plastic, paint, etc.) coatings upon small-size articles made of ferromagnetic materials.

- measurement range, T: 0-300 µm (0.3 mm);

- measurement accuracy: ±(0,02T+1) µm;

- diameter of test area, Øm, mm: 4 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 4,5 (1);

- dimensions, mm: Ø9×65.

Particulars

Wear-resistant probe with spring-loaded measuring system for control of galvanic coatings, provides complete tuning out from influence of coating ’ s electric conductivity.

F2

Probe for dielectric (paint, powder, anode oxide, etc.) and current-conducting non-ferromagnetic (zinc, chrome, etc.) coatings upon articles made of ferromagnetic materials within the range of up to 3 mm.

- measurement range, T: 0-3000 µm (3 mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, Øm, mm: 6 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 9,0 (1,5);

- dimensions, mm: Ø20×90.

Particulars

probe with spring-loaded measuring system. Use of hard-metal material for the tip allows to exclude its wear-out.

F2-mini

Probe for dielectric (paint, powder, anode oxide, etc.) and current-conducting non-ferromagnetic (zinc, chrome, etc.) coatings upon articles made of ferromagnetic materials within the range of up to 3 mm.

Technical features

- measurement range, T: 0-3000 µm (3 mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, Øm, mm: 6 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 9,0 (1,5);

- dimensions, mm: Ø9×65.

Particulars

probe with spring-loaded measuring system. Use of hard-metal material for the tip allows to exclude its wear-out.

F3

Probe for dielectric (paint, powder, anode oxide, etc.) and current-conducting non-ferromagnetic (zinc, chrome, etc.) coatings upon articles made of ferromagnetic materials within the range of up to 6 mm.

- measurement range, T: 0-6000 µm (6 mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, Øm, mm: 8 ;

- minimum diameter of substrate, mm, Øconc ( Øconv): 10,5 (2,5);

- dimensions, mm: Ø19×83.

Particulars

probe with spring-loaded measuring system for thick coatings.

F4

Thickness measurement of bitumen, plastic, foil, heat resistant and other non-ferrous coatings (including special purpose coatings) on substrates from steel with average and large surface roughness.

Technical features

- measurement range, T: 0-8000 µm (0-8 mm);

- accuracy in measurement range: 0–6 mm: ≤±(0,015T +0,01) mm; 6–8 mm: ≤±0,02T;

- minimum diameter of substrate, outer diameter/inner diameter, mm : 5/18,5;

- diameter of test area Øm, mm: 12;

- dimensions, mm: Ø15×49.

F5

Thickness measurement of bitumen, plastic, foil, heat resistant and other non-ferrous coatings (including special purpose coatings) on substrates from steel with average and large surface roughness.

Technical features

- measurement range, T: 0-1000 µm (0-10 mm);

- accuracy in measurement range: 0-10 mm 1–8 mm: ≤±(0,015T+0,01) mm; 8–10 mm: ≤±0,02T;

- minimum diameter of substrate, outer diameter/inner diameter, mm : 7/57;

- diameter of test area Øm, mm: 17;

- dimensions, mm: Ø23×58.

Probes for the Eddy-Current measurement method

Probes NF for K6-C contain one calibration characteristics for coatings thickness measurement on non-ferromagnetic bases.

NF0

Probe for measuring of dielectric (paint, anode oxide, powder, etc) and current-conducting non-ferromagnetic (tin, zinc, etc.) coatings upon articles made of current-conducting non-ferromagnetic materials within the range of up to 500 µm.

- measurement range, T: 0-500 µm (0,5mm);

- measurement accuracy: ±(0,02T+1) µm;

- diameter of test area, mm: 1,5 ;

- size, mm: Ø6×35.

Particulars

Probes with spring-loaded measuring system. Utilization of modern durable materials provides high strength and wear resistance of probe.

NF1

Probe for measuring of thickness of dielectric (paint, anode oxide, powder, etc) and current-conducting non-ferromagnetic (tin, zinc, etc.) coatings upon articles made of current-conducting non-ferromagnetic materials within the range of up to 2000 µm,

Technical features

- measurement range, T: 0-2000 µm (2mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, mm: 4,7 ;

- size, mm: Ø6×35.

Particulars

Probes with spring-loaded measuring system. Utilization of modern materials provides high strength and wear resistance of probe.

NF2 – NF4

Probe for measuring of thick dielectric coating (up to 60 mm) on metal substrates

Technical features

NF2

- measurement range, T: 0-15000 µm (15mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, mm: 20 ;

- minimum radius of base, mm, Øconc ( Øconv): 12 (5);

- size, mm: Ø15×85.

NF3

- measurement range, T: 0-30000 µm (30mm);

- measurement accuracy: ±0,02T µm;

- diameter of test area, mm: 40 ;

- minimum radius of base, mm, Øconc ( Øconv): 45 (15);

- size, mm: Ø23×88.

NF4

- measurement range, T, mm: 0-70;

- measurement accuracy, mm, 0-40 mm: ≤( 1% ± 0,1); 40-70 mm: 2%;

- diameter of test area, mm: 90;

- minimum radius of base, mm, Øconc ( Øconv): 270 (80);

- size, mm: Ø80×60.

Particulars

probes with spring-loaded measuring system. High temperature and stability of indications during work in field conditions.

Probes for the Eddy-Current phase measurement method

Probes PH for K6-C contain one “coating/base” characteristics.

PH1

Probe for measuring of the electrolytic nickel and other galvanic coatings upon steel substrates.

- measurement range, T, µm: 0-120;

- measurement accuracy, µm: ≤±( 0,03T + 1);

- minimum radius of base, mm : 1;

- diameter of test area, mm: 4,7 ;

- size, mm: Ø12×40.

Particulars

Possibility of control of galvanic coatings under dielectric layers.

PH3

Probe for measuring of galvanic coatings.

Technical features: PH3-0,2 || PH3-1,8

- measurement range, T, µm: 0-120 || 40;

- measurement accuracy, µm: ≤±( 0,03T + 1) || ≤±( 0,03T + 1 );

- minimum radius of base, mm : 1 || 75;

- diameter of test area, mm: 1 || 1 ;

- size, mm: Ø6×50 || Ø6×50.

Particulars

Possibility of control of galvanic coatings under dielectric layers.

Specialized probes

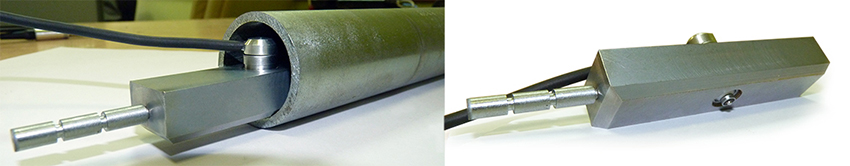

FxP, NFxP

Probe for measuring inside pipes made of ferromagnetic (FxP) and non-ferromagnetic (NFxP) materials.

- measurement range, T, µm: 0-2;

- measurement accuracy, µm: ≤±( 0,02T+ 0,001);

- minimum diameter of pipe, mm: 14;

- diameter of test area, mm: 4,7.

Particulars

Design of probes allows control in manual mode the pipes opened from two sides. Appliances for pilling probe depends on diameter and length of pipe.

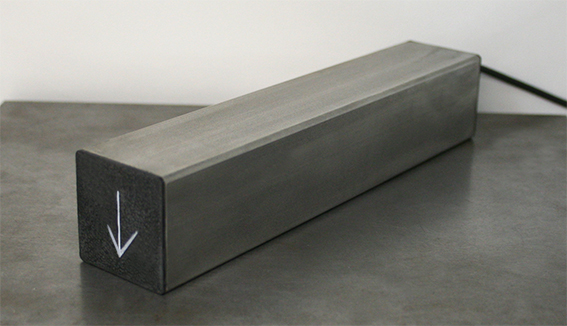

FR1

Probe for measuring of thickness of concrete down to rebar and determination of rebar location.

- measurement range, T, for concrete, mm: 70;

- measurement accuracy, mm: ≤±( 0,05T + 0,1);

- diameter of rebar, mm: 3-40;

- size, mm: 100x30x50.

Particulars

Possibility of operation in wide range of thickness of concrete and diameters of rebar.

FR2

Probe for measuring the thick protective coatings (up to 120 mm) on ferromagnetic surfaces.

- measurement range, T, mm: 1-120;

- measurement accuracy, mm: ≤±( 0,05T + 0,1);

- size, mm: 180x30x50.

R

Probe for roughness measurement after the sand and grit blasting prior to painting works.

Technical features

- roughness measurement range, µ m: 3-300;

- measurement accuracy, Rz: ≤± 0,02;

- size, mm: Ø12×45.

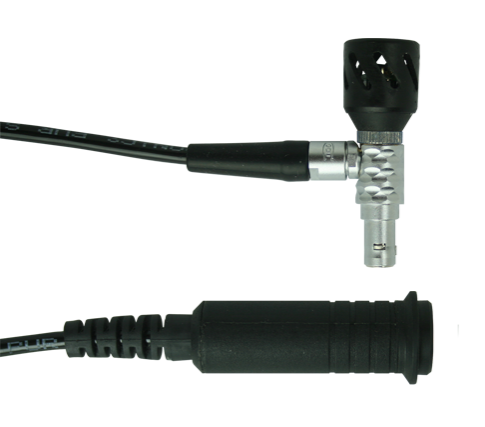

THDC

Probe for measurement of metal surface temperature, air temperature, relative air humidity, temperature of dew point and calculation of the difference between metal surface temperature and temperature of dew point (inspection of conditions during painting of metal products).

Data shown on device display

when THDC probe is connected

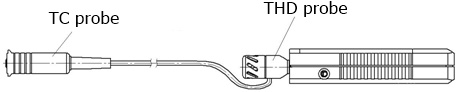

THD

Probe for measuring of air temperature, humidity and dew point during execution of paint works.

Technical features

1) measurement range:

- air temperature: -10°C – +40°C;

- humidity: 5-90%;

- dew point, °C: -15° – 40°.

2) measurement accuracy:

- humidity, °C : ≤± 5%;

- air temperature, °C: ±1 ° ;

- dew point, °C: ≤± 2 °.

3) size, mm: Ø15×120.

Particulars

probe of integral type with wide limits of measuring.

Related products

-

K5-C

Purpose Thickness measurement of: — dielectric (paint, lacquer, enamel, plastic, teflon, anodic oxide, mastic and other) coatings on products from […]

More -

Thickness meter – knife

ISO 2808, ASTM D4138, DIN EN1071-2 Purpose The instrument is designated to determine thickness of hardened coatings on any basis […]

More

+420 267 313 996

+420 267 313 996