KT-C

Product Description

Purpose

Small sized device with set of exchangeable transducers designated for hardness measurement and tensile strength σ of wide range of materials.

According to operating principle the device carry out the following measurements methods:

— dynamic method (Leeb method) in accordance with ASTM A956 standard (ISO 16859-1);

— UCI (ultrasonic contact impedance) method;

— static method of hardness measurement in accordance with ASTM B724 standard;

— hardness measurement method according to Shore A in accordance with EN ISO 868 (DIN 53505, ASTM D2240).

Features

— the first device that comprises 4 measurement methods, universal instrument for hardness determination of metals and plastics;

— wide range of measuring transducers and accessories for control of products of various shapes and dimensions;

— colour 2.4’’ display with built-in Li-Ion rechargeable battery;

— shock-proof ergonomic body with rubberized corners;

— position of transducer in relation to the horizon does not influence measurement results;

— possibility of application in both laboratory and manufacturing conditions;

— possibility of quick view of statistics in measuring process with averaging and by groups stored in device memory;

— possibility of control with set value limits;

— measurement results can be stored in device memory for further transfer into PC using USB 2.0 channel for storage, statistical processing and documentation with use of supplied software.

Basic technical characteristics

| Hardness scales | HRC, HB, HV, HRA, HRB, HSD, σ, HL |

| Basic measurement error*: | |

| for Brinell, НВ | 10 |

| for Vickers, НV | 12 |

| for Shore, НSD | 2 |

| for Rockwell, НRC | 1,5 |

| for Leeb, % | ± 3,0 % (100…500 HLD, 100…700 HLDL, 100… 600 HLC, 100…450 HLG)

± 3,0 % (500…700 HLD, 700…850 HLDL, 600…750 HLC, 450…600 HLG) ± 2,0 % (>700 HLD, >850 HLDL, >750 HLC, >600 HLG) |

| Tensile strength (σ), %, max | 5 |

| Number of measurements for average value calculation | up to 99 |

| Number of memory locations of the measurement results | up to 1000 (can be stored into 99 groups) |

| Power supply | built-in Li-Ion rechargeable battery 3.7-4.2 V, 1500-1700 mAh |

| Operating time, h | 12 |

| Working temperature range | -30…+40 °С |

| Dimensions, mm | 125 x 55 x 20 |

| Weight, g | 120 |

* These characteristics of measurement error are ensured on hardness test blocks with averaging from at least 10 measurements.

Delivery set

Delivery set

Measuring unit with transducers (quantity and modification depends on customer’s selection), сharging unit, mini-USB — USB type A cable for connection with computer, operating manual, CD with software for transfer and collection of measuring results, shock-proof case.

Guarantee period

— measuring unit — 3 years;

— transducers — 2 years.

KT-C Leaflet to download below

KT-C

Materials, hardness scales, measurement ranges

| Materials | Hardness scale | Hardness measurement range | |||||

| Leeb | UCI | Portable Rockwell | |||||

| D, DC | DL | G | C | U-10N

U-50N U-100N |

SPR | ||

| Plain steel, low alloyed steel, cast steel | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | |

| HB | 75-654 | 81-646 | 90-646 | 81-694 | 75-654 | 75-654 | |

| HV | 75-1000 | 80-950 | – | 81-1012 | 75-1000 | 75-1000 | |

| HRC | 20-70 | 21-67 | – | 20-70 | 20-70 | 20-70 | |

| HRA | 60-93 | – | – | – | 60-93 | – | |

| HRB | 25-100 | 37-100 | 48-100 | – | 25-100 | – | |

| HSD | 20-100 | 31-97 | – | 30-102 | 20-100 | – | |

| σ, MPa | 370-1740 | 370-1740 | 370-1740 | 370-1740 | 370-1740 | – | |

| Tool steel | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HV | 80-900 | 80-905 | – | 98-942 | – | – | |

| HRC | 20-70 | 21-67 | – | 20-67 | – | – | |

| Stainless steel | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 85-655 | – | – | – | – | – | |

| HV | 85-802 | – | – | – | – | – | |

| HRC | 20-62 | – | – | – | – | – | |

| Grey cast iron | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 90-664 | – | 92-326 | – | – | – | |

| Ductile iron | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 95-686 | – | 127-364 | – | – | – | |

| Aluminium alloys | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 19-165 | 20-187 | 19-168 | 21-167 | 19-165 | 75-450 | |

| HV | – | – | – | – | – | 75-1000 | |

| HRB | 24-85 | 24-85 | 28-86 | 23-85 | 24-85 | ||

| Brass (copper and zinc alloy) | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 40-173 | – | – | – | 40-173 | 75-450 | |

| HV | – | – | – | – | – | 75-1000 | |

| HRB | 14-95 | – | – | – | – | ||

| Bronze (copper and aluminium alloy / copper and tin alloy) | HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 60-300 | – | – | – | 60-300 | 75-450 | |

| HV | – | – | – | – | – | 75-1000 | |

| Forged copper

|

HL | 0-1000 | 0-1000 | 0-1000 | 0-1000 | – | – |

| HB | 45-315 | – | – | – | – | 75-450 | |

| HV | – | – | – | – | – | 75-1000 | |

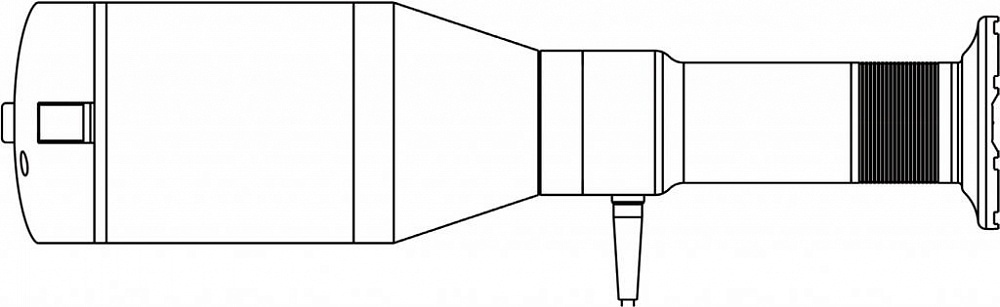

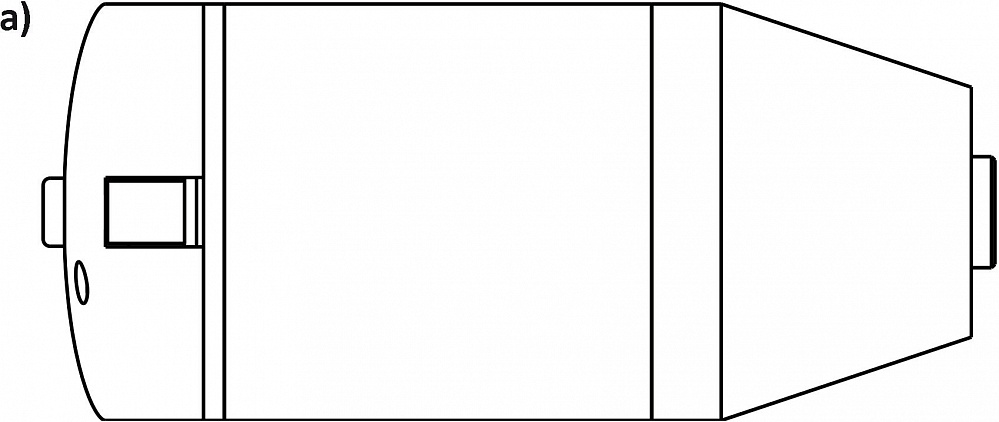

Dynamic (Leeb) probes for KT-C Hardness Tester

D

Basic technical characteristics:

— dimensions, mm: Ø23 x 139;

— roughness Ra, µm: 3.2;

— min metal thickness, mm: 10.

C

Basic technical characteristics:

— dimensions, mm: Ø23 x 139;

— roughness Ra, µm: 1.6;

— min metal thickness, mm: 5.

DL

Basic technical characteristics:

— dimensions, mm: Ø23 x 255;

— roughness Ra, µm: 3.2;

— min metal thickness, mm: 10.

G

Basic technical characteristics:

— dimensions, mm: Ø32 x 248;

— roughness Ra, µm: 12.5;

— min metal thickness, mm: 70.

Ultrasonic (UCI) probes for KT-C Hardness Tester

U-10N

Basic technical characteristics:

Pressure Force 9.8 N.

— min metal thickness, mm, 2;

— min radius for test, mm, 5;

— max surface roughness Ra, µm, 0,8;

— dimensions Ø26 x 140.

U-50N

Basic technical characteristics:

Pressure Force 49 N.

— min metal thickness, mm, 2;

— min radius for test, mm, 5;

— max surface roughness Ra, µm, 1,6;

— dimensions Ø26 x 140.

U-100N

Basic technical characteristics:

Pressure Force 98 N.

— min metal thickness, mm, 2;

— min radius for test, mm, 5;

— max surface roughness Ra, µm, 3,2;

— dimensions Ø26 x 140

SPR-A (Portable Rockwell) probe for KT-C Hardness Tester

The probe is designed to measure the hardness of non-ferrous metals and alloys (aluminum, copper, titanium and their alloys, etc.), all types of steels and alloys of low and medium hardness (structural, carbon, alloyed, stainless, heat-resistant, etc.) and other materials (fiberglass, engineering plastics, etc.).

The SPR-A probe is completely identical to the SPR probe and is equipped with an automatic load application module. In this case, when making measurements, the operator will not need to make efforts to take measurements, it will only be necessary to hold the probe on the surface whose hardness is to be measured.

The measurement is started by pressing the button located on the top cover of the module. By automating the process of applying the measuring load during the measurement process, the human factor is eliminated, the repeatability and reproducibility of the measurement results is increased.

The automatic load application module is powered by a built-in Li-Ion battery.

| Measurement error of penetration depth, max, µm | ±0.3(ASTM E18–03) |

| Load: | |

| Preliminary, N, (kg) | 10 (1) |

| Preliminary and main load, N, (kg) | 50 (5) |

| Diamond indenter – truncated cone: | |

| Sharpening angle, degree | 100±0.5 |

| Overall dimensions total, mm | Ø60×225 |

| Overall dimensions of the module*, mm | Ø60×130 |

| Weight total, g | 1050 |

| Module weight*, g | 730 |

| Time of one measurement, sec | 5-7 |

| Number of measurements per charge cycle, not less than | 100 |

* technical characteristics of a single automatic load application module without a connected probe

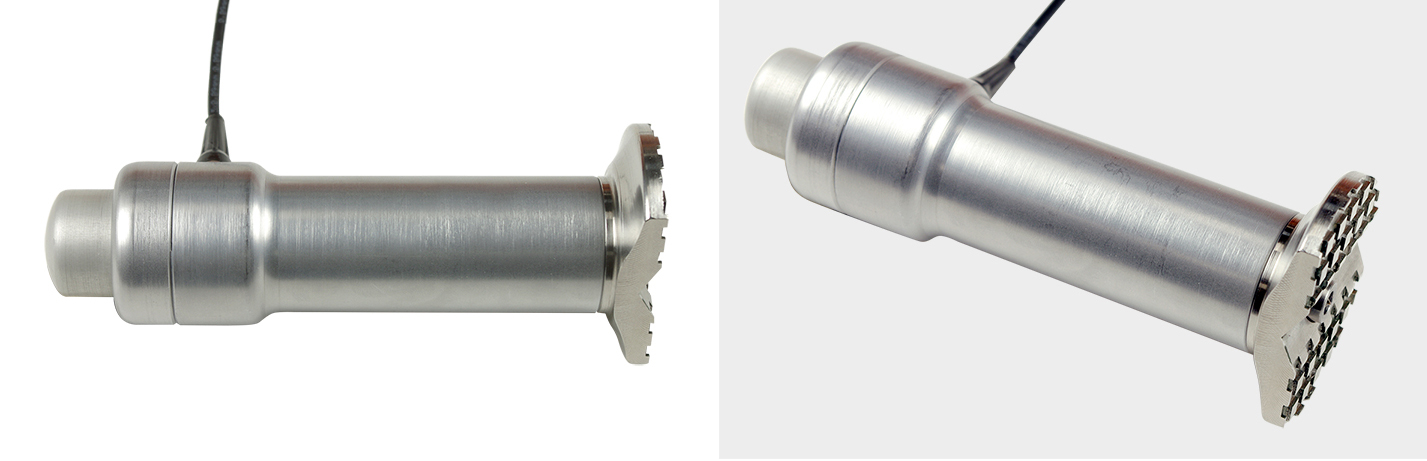

SPR (Portable Rockwell) probe for KT-C Hardness Tester

The probe is designated to measure hardness of nonferrous metals and also steels with low and medium hardness and other materials. The device realizes direct method of hardness measurement in accordance with DIN 50157 and ASTM B724 standards. It is possible to measure hardness of surface layers, parts sensitive to scratches and polished surfaces and also thin products, profiles, pipes with wall thickness less than 2 mm. Material and dimensions of inspected objected do not influence measurement results.

Features:

— direct measurement method;

— possibility to measure hardness of a wide range of materials (nonferrous metals and alloys, steels, plastics) without preliminary calibration;

— absence of thickness influence (from 2 mm) and weight influence of inspected object on measurement results;

— possibility to carry out measurements with set limits.

Basic technical characteristics:

— indentation depth measurement error, µ: ± 0,3 (ASTM E18-03) ;

— load:

- preliminary, N: 12;

- preliminary and main load, N: 49;

— diamond indenter – truncated cone:

- angle of lateral side, degree: 100 ± 0,5;

- diameter of the upper base, µm: 60 ± 5 ;

— Overall dimensions, mm: Ø53 х 104 ;

— Weight, g: 300.