K2.2 HOLIDAY DETECTOR

Product Description

Purpose

The detector is designed to reveal cracks, porosity, inadmissible thinning and other continuity violation of inner and outer protective coatings on metallic products with application of pulsed high voltage while an electric spark is fixed by the device in the place of continuity violation or inadmissible thinning.

Features

Features

— adjustable output voltage range: 2,5–40 kV;

— maximum controlled thickness of insulating coatings: up to 16 mm;

— digital display showing voltage on electrode;

— high stability of voltage on electrode;

— possibility of sensitivity adjustment;

— quick battery replacement;

— possibility to charge battery separately from control unit;

— high safety due to pulsed operation mode;

— large selection of replaceable electrodes to control articles used for different purposes;

— possibility of using specialized disc electrodes for coating inside tubes with diameter from 89 to 520 mm and length up to 14 m;

— small dimensions and light weight;

— possibility to control coatings on concrete frame.

Basic technical characteristics

— Type of indication of voltage amplitude on electrode– digital (3-digit);

— Output voltage adjustment resolution: 0,1 kV;

— Diameter of controlled pipes while using spring electrodes: up to 1600 mm;

— Diameter of controlled pipes during internal insulation inspection while using disc electrodes: from 60 mm to 1600 mm;

— Device power source — built-in rechargeable battery: industrial for temperature range: -20 °C…+45 °C; low-temperature for temperature range: -45 °C…+45 °C; inspection voltage stability: 2 %;

— Weight: control unit (with battery): 2 kg; high-voltage transformer-holder VT2 – 1,3 kg;

— Operating time from charged battery: up to 8 hours;

— Overall dimensions: control unit: 240 × 149 × 52; high-voltage transformer-holder VT2 – 57 × 380 mm.

Delivery set

Delivery set

High-voltage transformer-holder VT2, control unit, brush (fan) electrode and T-shaped electrode, extension rod, charging device, two rechargeable batteries, earth rod, magnet, earth lead, operating manual, thermo bag, case for storage and transportation.

The device may be completed with additional rechargeable batteries and also with the following replaceable electrodes:

— T-shaped electrode of small dimensions, crescent-shaped electrode, brush (fan) electrode, flat, rubber and hair electrodes with inspection zone from 50 to 400 mm;

— Spring electrodes with one clamping for pipe diameter up to 1520 mm.

K2.2 Leaflet to download below

Holiday detectors

______________________________________________________________________________________________________________________________________

Electrodes

Rolling spring electrodes

Used to test insulating coatings on the outside surface of pipes. Available for pipes from 80 to 1620 mm diameter.

– Electrode B19 is made of beryllium bronze, spring diameter 19 mm. Designed for discontinuity testing of external coating on pipe with diameter from 80 to 424 mm.

– Electrode S19 is made of spring steel, spring diameter 19 mm. Designed for discontinuity testing of external coatings on pipes with diameter from 159 to 629 mm.

– Electrode S32 is made of spring steel, spring diameter 32 mm. Designed for discontinuity testing of external coatings of pipes with diameter from 425 to 1620 mm.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

Internal pipe disk electrodes

Used to inspect insulating coatings inside pipes with the diameter from 30 to 1420 mm.

Crescent-shaped electrodes

Designed to define places of continuity violation on insulating coatings of the pipes from 25 to 1020 mm diameter.

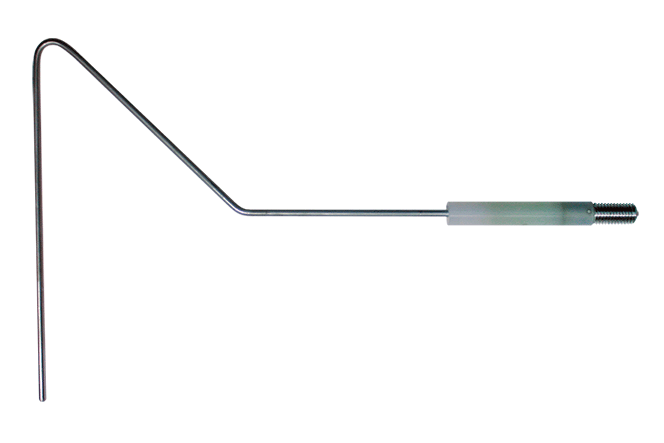

T-shaped electrodes

Used to test dielectric coatings of flat products.

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Round silicone rubber electrodes (with hole): Used to test coatings on the outside of small pipes (from 25 mm diameter).

Curved silicone rubber electrodes: Used for testing the external surface of pipes.

Rubber ring electrodes: Used for inspection of the outer surface of pipes with the diameter from 30 to 1420 mm

Special electrodes can be made according to customer’s own specification.