CORONA 40

Product Description

CORONA 40 – Holiday detector

Corona 40 is a portable autonomous device for detecting pores, scratches, cracks, chips, tears, leaks and other defects in protective dielectric coatings with the application of pulsed high voltage while an electric spark is fixed by the device in the place of defect.

Features

Features

– High accuracy of maintaining the test voltage on the electrode (not more than 2%);

– Powerful test voltage generator (up to 50 W);

– False defect detection system;

– The device has a digital interface containing:

1. test voltage calculator, which allows to calculate the test voltage based on the known thickness of the tested coating;

2. user calibration mode, which allows to correct the device calibration by the user during the entire device lifetime if the appropriate measuring equipment is available;

3. single-electrode testing mode, allowing to detect through coating defects without a connected earthing wire;

4. defect counter;

– Operating temperature range: from minus 40 °C to plus 50 °C;

– The weight of the control unit does not exceed 0.65 kg;

– Autonomous operation time (up to 20 h at a test voltage of 40 kV using a fan electrode).

Basic technical characteristics

| Technical data | Corona 40 |

| Minimum thickness of tested coatings, µm | 50 |

| Maximum thickness of tested coatings, mm, at least | 25 |

| Type of holiday detector | Pulsed |

| Test voltage range, kV | From 0.7 to 40 |

| Pulse frequency, Hz | 50 |

| Voltage setting error, maximum | 2% |

| Weight of the control unit, g, maximum | 650 |

| Overall dimensions of the control unit (DxWxW), mm, maximum | 240х149х50 |

| Overall dimensions of the high-voltage transformer-holder (ØxD), mm, maximum | Ø83х380 |

Delivery set

Control unit Corona 40, case for control unit, high-voltage transformer-handle VT-40, ground wire with magnet and crocodile clip, extender, battery, fan electrode, battery charger, operating manual.

Electrodes

Rolling spring electrodes

Used to test insulating coatings on the outside surface of pipes. Available for pipes from 80 to 1620 mm diameter.

– Electrode B19 is made of beryllium bronze, spring diameter 19 mm. Designed for discontinuity testing of external coating on pipe with diameter from 80 to 424 mm.

– Electrode S19 is made of spring steel, spring diameter 19 mm. Designed for discontinuity testing of external coatings on pipes with diameter from 159 to 629 mm.

– Electrode S32 is made of spring steel, spring diameter 32 mm. Designed for discontinuity testing of external coatings of pipes with diameter from 425 to 1620 mm.

Brush (fan) electrode

Designed to inspect dielectric coatings of complex profile.

Brush (hair) electrode

Designed to inspect dielectric coatings with complex profile and larger area.

Internal pipe disk electrodes

Used to inspect insulating coatings inside pipes with the diameter from 30 to 1420 mm.

Crescent-shaped electrodes

Designed to define places of continuity violation on insulating coatings of the pipes from 25 to 1020 mm diameter.

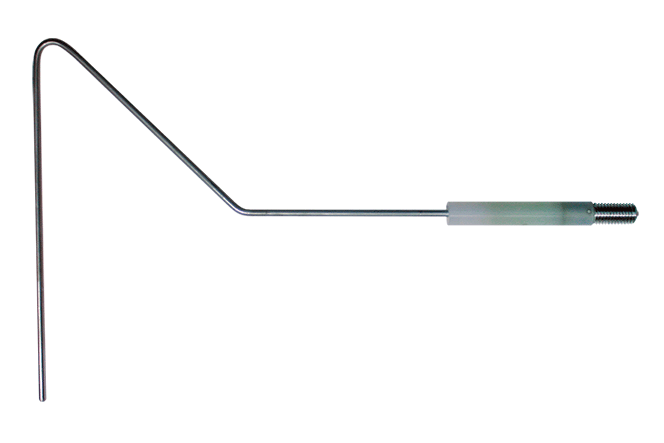

T-shaped electrodes

Used to test dielectric coatings of flat products.

T-shaped tubular electrode (mountable)

Designed to inspect flat dielectric coatings, usually large areas like the roofs of buildings. Manufactured from 200 to 1000 mm. Since it is mountable, the width is adjustable.

Silicone rubber electrodes

Designed to define places of continuity violation on insulating coatings.

Straight silicone rubber electrodes: Suitable for testing coatings on larger flat surfaces.

![]()

Round silicone rubber electrodes (with hole): Used to test coatings on the outside of small pipes (from 25 mm diameter).

Curved silicone rubber electrodes: Used for testing the external surface of pipes.

Rubber ring electrodes: Used for inspection of the outer surface of pipes with the diameter from 30 to 1420 mm

Special electrodes can be made according to customer’s own specification.